Bay Towel’s Commitment to Food Safety: How We Implement SSOPs in Food Processing Textile Services

In today’s food manufacturing environment, cleanliness isn’t just a preference—it’s a regulatory requirement. Textiles used in food processing facilities, from frocks and pants to mats and towels, are now recognized as potential sources of microbial contamination. That’s why strict Sanitation Standard Operating Procedures (SSOPs) are essential for ensuring compliance and food safety.

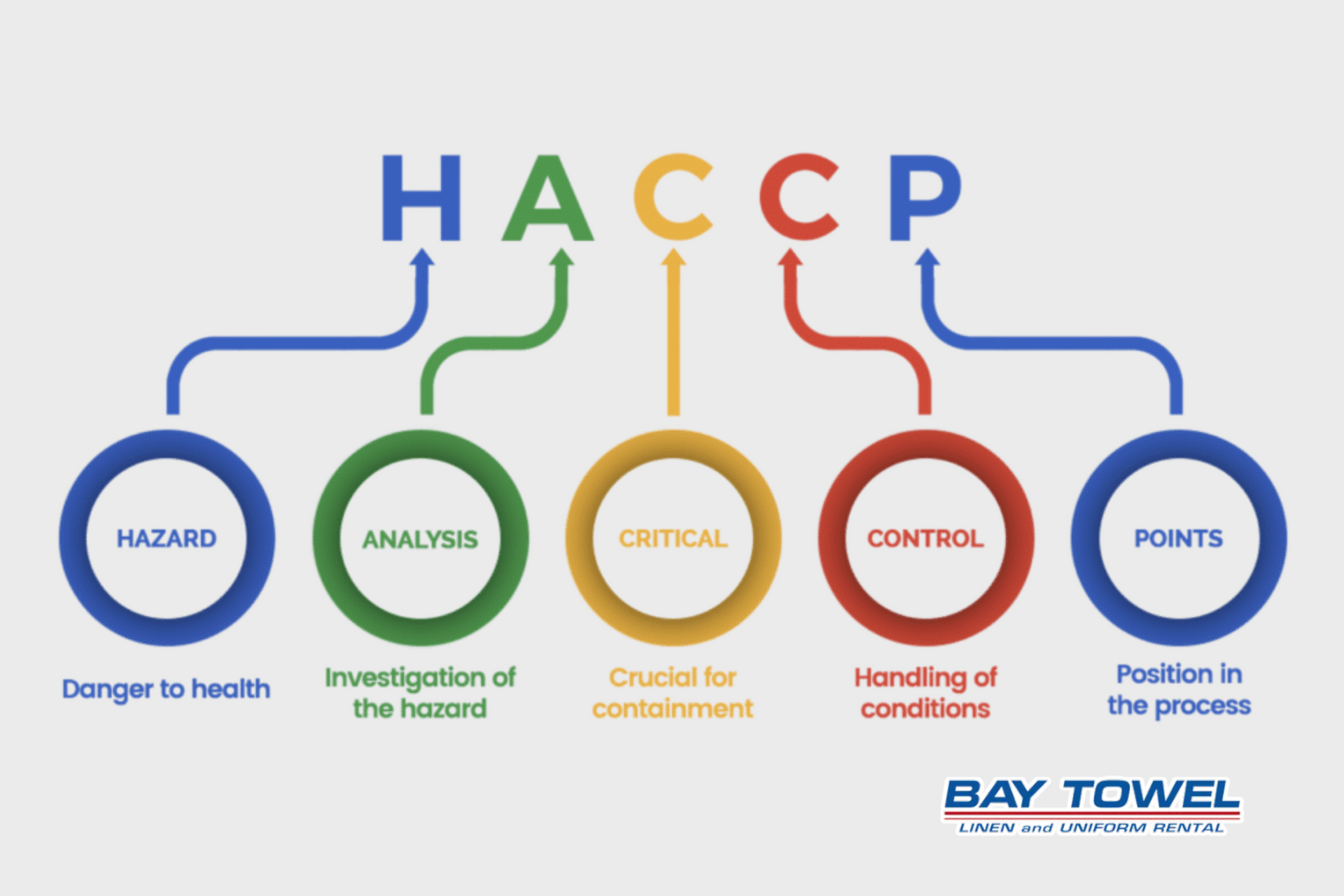

At Bay Towel, we go above and beyond to implement SSOPs that meet and exceed industry standards—ensuring our clients receive hygienically clean garments and textiles that fully support their HACCP and regulatory compliance goals.

🛡️ Regulatory Alignment: Cleanliness is the Law

The Code of Federal Regulations (21CFR, Part 110.10.B1) requires that food processing personnel—and their garments—be maintained in a condition of “cleanliness.” Bay Towel adheres to these regulations by treating every piece of food-related textile as a Critical Control Point (CCP).

Through our HACCP-aligned process, we identify potential hazards, establish controls, monitor effectiveness, and continually verify that our laundering system operates within compliance.

🧼 Engineered Wash Formulas & Temperature Control

What Bay Towel Does:

- Garments are washed at a minimum of 149°F for 10 minutes to destroy pathogens.

- Soaps and detergents used have both soil-lifting and antimicrobial properties.

- A drying/steaming phase at 270–290°F adds an extra layer of sanitation.

We validate this process regularly and provide documentation through our “Hygienically Clean” Certification specific to the food industry.

⚙️ Equipment Maintenance & Performance Monitoring

Bay Towel uses proprietary monitoring systems that track and log data from each piece of laundering equipment:

- All systems are calibrated and maintained to perform as programmed.

- A dashboard reporting system provides real-time performance metrics.

- All processes are validated and monitored with records kept between validations to ensure consistent results.

🚫 Cross-Contamination Controls Within the Facility

Separation is key. Bay Towel’s laundering facility is designed to physically separate clean and soiled textiles.

- Barriers and posted traffic routes reduce the risk of clean items being contaminated.

- Only authorized personnel are allowed in clean processing areas.

- Hand hygiene stations with instant sanitizers are placed throughout the facility.

🐜 Pest Control & Hygiene Practices

Bay Towel follows Integrated Pest Management (IPM) principles to mitigate contamination risk from pests.

Additional Hygiene Controls Include:

- Hand sanitizer use by employees handling clean garments.

- Regularly updated policies to support hygiene across departments.

👕 Garment Design for Food Safety

Bay Towel supplies specialized garments designed specifically for food processing environments:

- No buttons or pockets to trap contaminants.

- Color-coded uniforms help supervisors identify employees by role or department, improving compliance monitoring.

- All garments go through a step-by-step quality inspection before returning to customers.

🔬 Microbial Testing Protocol

We don’t just say our garments are clean—we test and prove it.

- A fabric swatch (2" x 5") is aseptically removed and processed.

- After incubation on Tryptic Soy Agar, colony counts are measured.

- Results must be under 50 CFU per square inch to be considered hygienically clean.

This protocol ensures that all garments meet strict microbial safety standards before they’re returned to food clients.

🚛 Safe Distribution & Delivery Practices

Even the cleanest garments can be compromised during transportation. Bay Towel implements multiple safeguards:

1. Poly Carts

- All delivery carts are sanitized and lined with disposable plastic to prevent contact contamination.

2. Cross-Contamination Control on Routes

- Clean garments are placed in sealed laundry bags, stored in designated areas on the truck.

- Drivers use hand sanitizer or gloves before delivering clean items and after handling soiled ones.

3. Employee Training

- Bay Towel service staff are regularly trained on:

- Cross-contamination risks

- Food safety procedures

- How to handle clean/soiled garments at customer facilities

4. Truck Cleanliness

- Service trucks are kept free of dust and debris, with a clear separation between clean and soiled textiles.

5. Mat Cleaning

- Mats are cleaned and changed out on a set schedule to ensure cleanliness at plant entry points.

📑 Documented and Verified Processes

Bay Towel’s SSOP system is backed by:

- HACCP Flowcharts

- Food Processing Coat Procedures

- Bay Towel Hygienically Clean Certification

These documents provide transparency and support regulatory audits for our food industry clients.

✅ Why It Matters

Bay Towel’s implementation of SSOPs ensures:

- Compliance with CFRs and food safety regulations.

- Risk reduction of microbial contamination.

- Peace of mind for food processors, packagers, and distributors.

Looking for a textile partner who takes food safety seriously?

Bay Towel’s proven SSOP system helps your facility meet compliance while keeping your workforce protected and your product safe.

📩 Contact us today to learn more or request a hygiene audit for your facility.